Views: 0 Author: Ada Liu Publish Time: 2024-08-13 Origin: Site

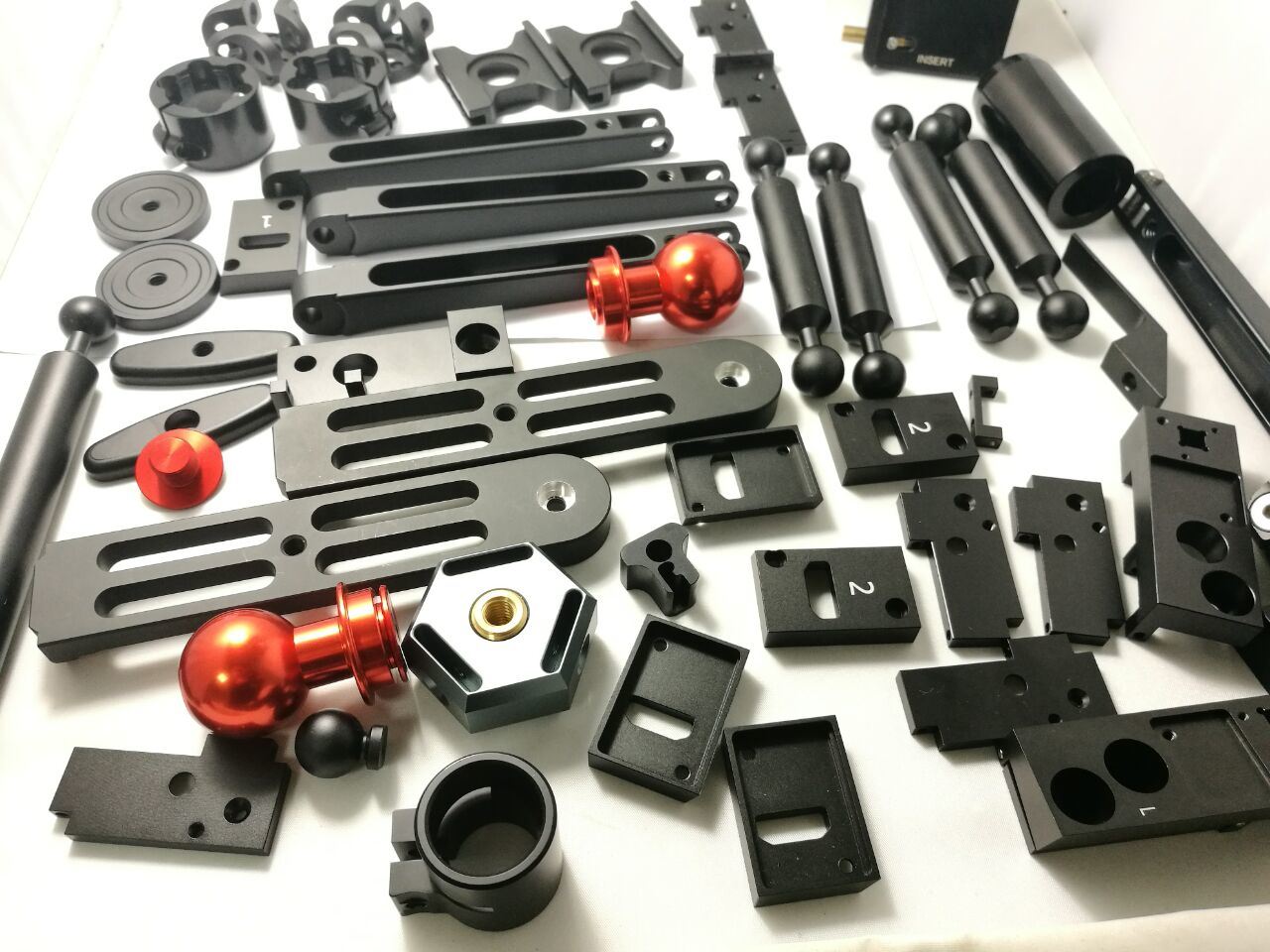

As a cnc machining manufacturer, most of machined parts is metal parts, like aluminum parts, steel parts, brass parts and Ti parts. when we quote to customers, some customers have a very clear positioning of their products, will clearly tell us the materials and models needed, but some customers are not too clear about what materials are needed for their products, or what materials can be, we will give customers some advice: the choice of materials for metal products should be based on the purpose of use, working environment, shape and size and other factors for comprehensive consideration, now I will share normal materials in the article.

1. steel: steel has high strength, good tensile properties, wear resistance, corrosion resistance, etc., suitable for the manufacture of parts requiring high strength, such as machine tools, automobiles, construction machinery, etc.

2. aluminum: aluminum lightweight, good thermal conductivity, corrosion resistance, easy to process and molding characteristics, suitable for the manufacture of some of the parts need to be lightweight, such as aviation, shipping, electronics and other industries.

When selecting metal materials, cost, operability and reliability should also be considered to ensure that the selected material meets the requirements of use, for example, stainless steel is more expensive than aluminum alloy, aluminum alloy 7075 is more expensive than 6061, if the customer has no requirements on the strength of the material, then selecting 6061 can meet the basic requirements, if this product is a functional product, there are requirements on the strength and tensile, then we would recommend using 7075, but the price will be slightly higher