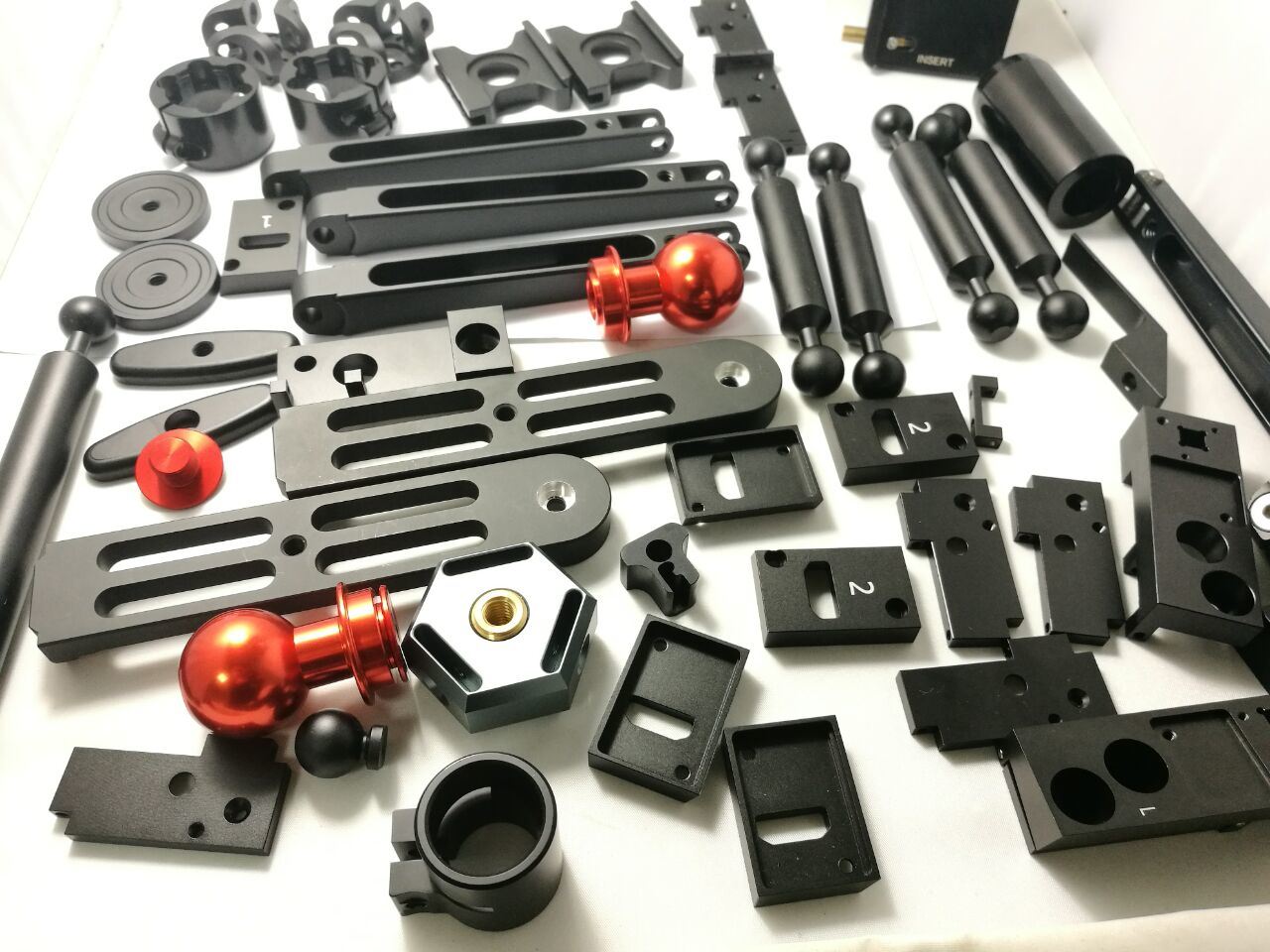

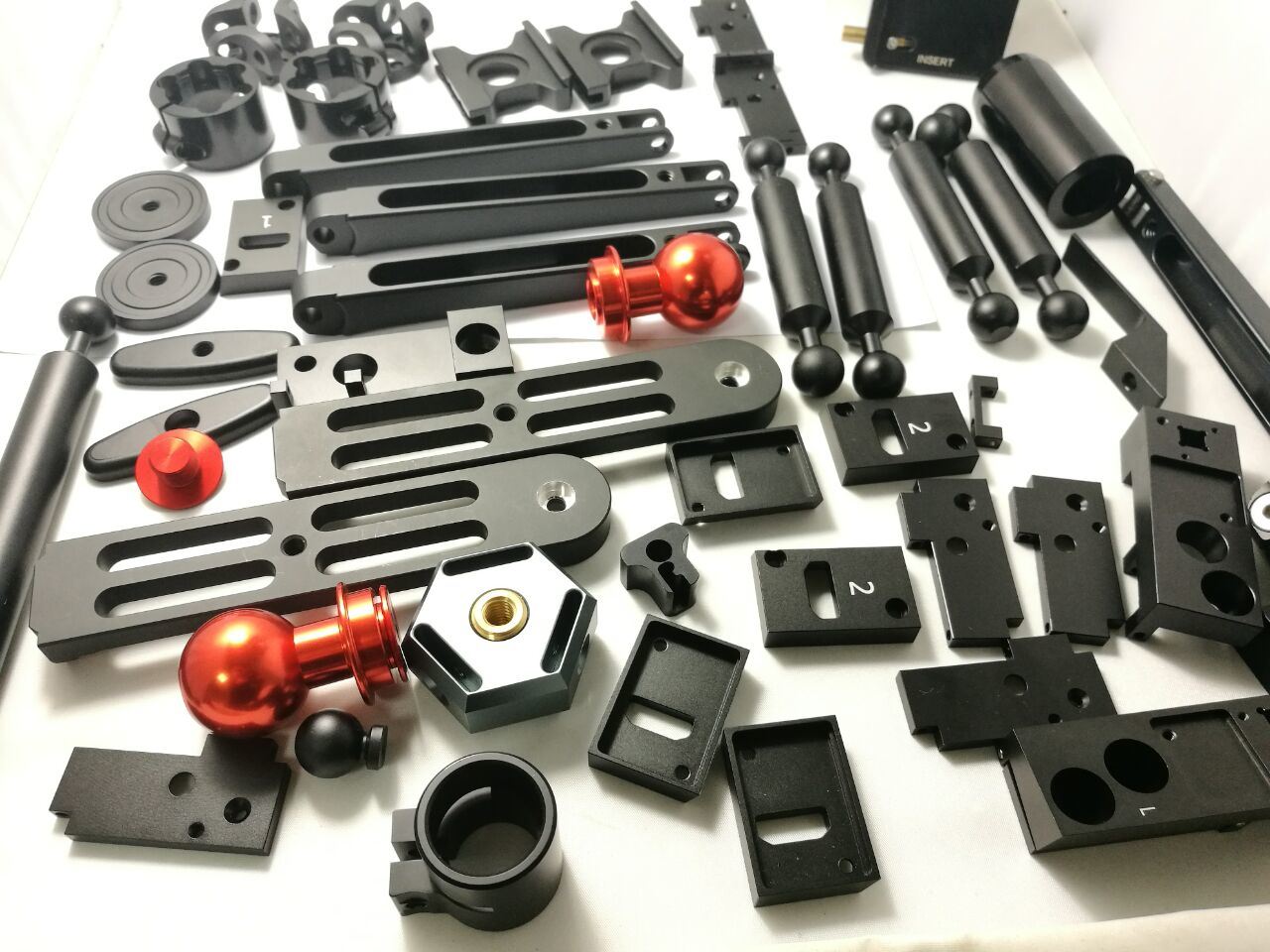

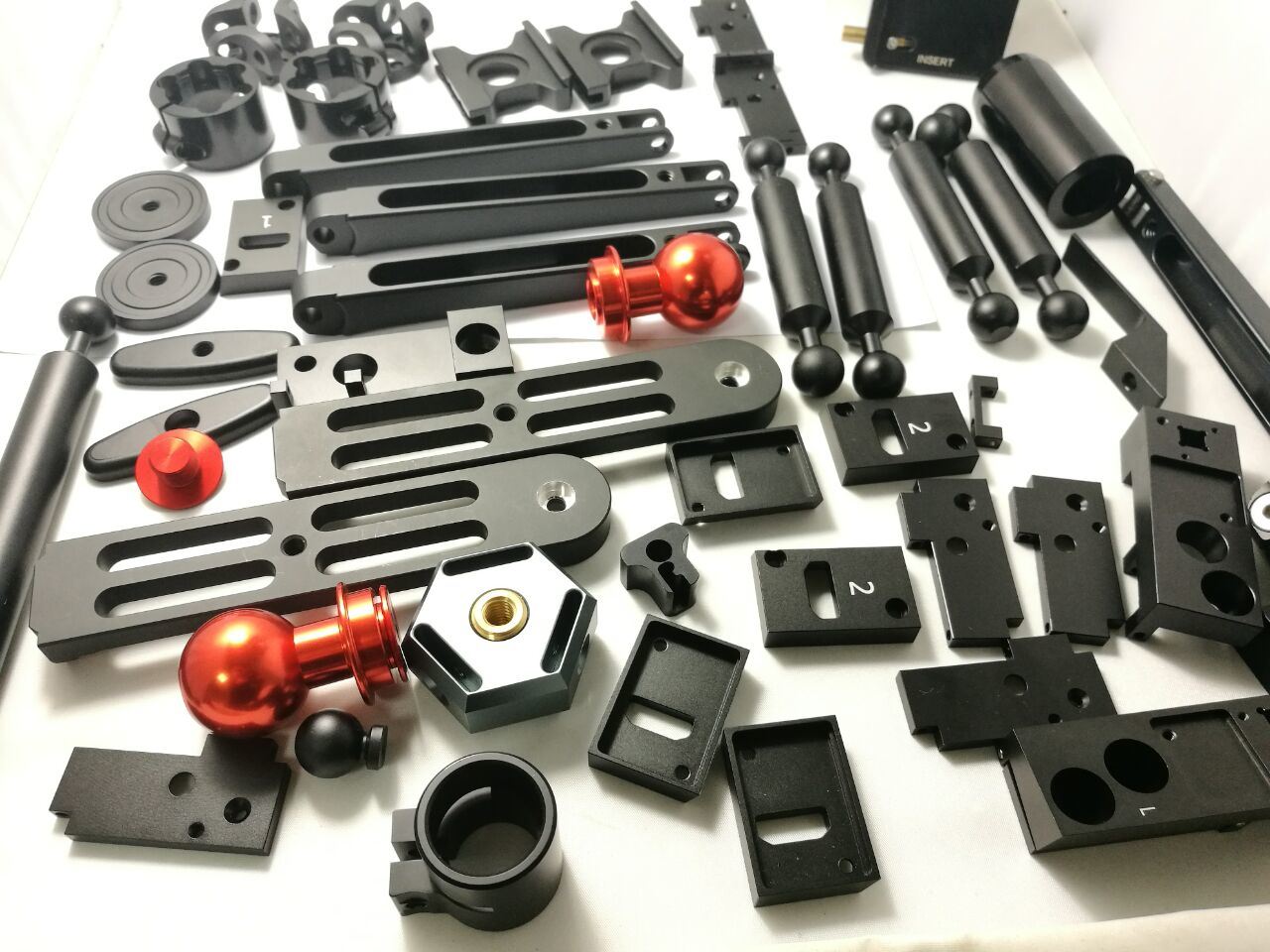

2024-08-13 As a cnc machining manufacturer, most of machined parts is metal parts, like aluminum parts, steel parts, brass parts and Ti parts. when we quote to customers, some customers have a very clear positioning of their products, will clearly tell us the materials and models needed, but some customers are

Read More

2024-08-06 After CNC machining steel parts, if you don't do surface treatment, It may be rust and look ugly after a long time, if you need to make a different colors, usually we suggest do powder coating or electroplating, today I will introduce in detail the electroplating and electrophoresis.Electroplating:

Read More

2024-08-05 After the aluminum machining process is completed, it turns into a very important surface finishing step for improving the quality lifespan and corrosion resistance of parts.SandblastingIn addition, by propelling abrasives onto aluminum surfaces sandblasting also removes oxides, oils, and contaminan

Read More

2024-07-18 Deburring is a common method for removing burrs from CNC machined parts, especially for complex shapes and hard-to-reach areas. We will arrange the deburring process step by step. Before starting the deburring process, we will choose the following tools and materials.• Files: for grinding and smoot

Read More

2024-07-16 A reflector is a round metal or plastic cup that is usually mounted on the front of a flashlight. By reflecting light, the reflector enhances the range and intensity of illumination, allowing the flashlight to illuminate longer distances. Reflectors are usually categorized into glossy and orange pee

Read More

2024-07-15 When completing CNC custom processing parts and starting assembly, plastic components are often needed. The most common materials used are TPU (Thermoplastic Polyurethane) and silicone. These two materials have distinct characteristics, and the choice can be made based on specific requirements. 1. M

Read More