Views: 0 Author: Site Editor Publish Time: 2024-08-02 Origin: Site

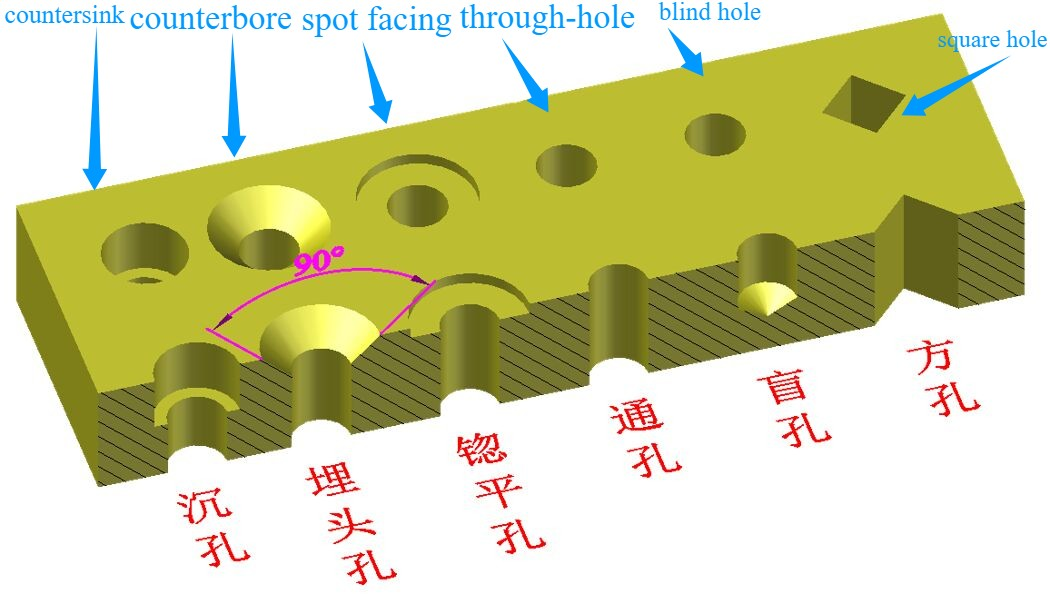

Countersink

Definition: Countersinking is a machining process that creates a larger diameter recess on the surface of a material, designed to accommodate the head of a screw so that it sits flush with or below the surface.

Characteristics:

1. Appearance: Features a larger diameter recess, typically conical or cylindrical.

2. Purpose: Mainly used to hide the screw head, ensuring it does not protrude above the surface for a more aesthetically pleasing and safe assembly.

3. Tools: Uses specialized countersink drill bits or milling cutters.

Through Hole

Definition: A through hole is a hole that extends completely through the thickness of a material, used for connecting, fastening, or passing through components.

Characteristics:

1. Appearance: Penetrates the entire material, usually round, but can be other shapes.

2. Purpose: Used for screws, bolts, or as a pathway for pipes and wires.

3. Tools: Created using a drill press, handheld drill, or CNC machine.

Summary of differences

1. Shape and purpose: Countersink holes are grooves designed to hide the head of a screw, while through holes are holes through the material for fastening or conduction.

2. Machining methods: Countersink holes are machined using Countersink drills or milling cutters, while through holes are machined using regular drills or CNC equipment.

3. Application scenarios: Both are widely used, but the specific uses are different. Countersink holes are used more for aesthetic and safety considerations, while through holes are used for fixing and connecting.