2024-08-13 We are a professional CNC machining factory, the material we can make vary from Aluminum, Stainless steel, Brass, Copper, Titanium, POM, Delrin, Teflon and so on, while some customers always ask why our parts is made of Stainless steel and get rust sometimes, here I’d like to you know why. There are

Read More

2024-08-10 Gradient anodizing is a sophisticated surface treatment technique used to create visually stunning effects on metal components, particularly aluminum. This process imparts a smooth, color-gradient finish to the metal, blending hues seamlessly from one shade to another. Gradient anodizing is a variat

Read More

2024-08-05 As a processional CNC machining center, to meet our customers requirement, we have our own LASER CUT machines now, this machine can cut material under 10mm. With this machine added, we can shorten order lead time and improve laser cut outercourse quality. If you have some laser cut related parts ne

Read More

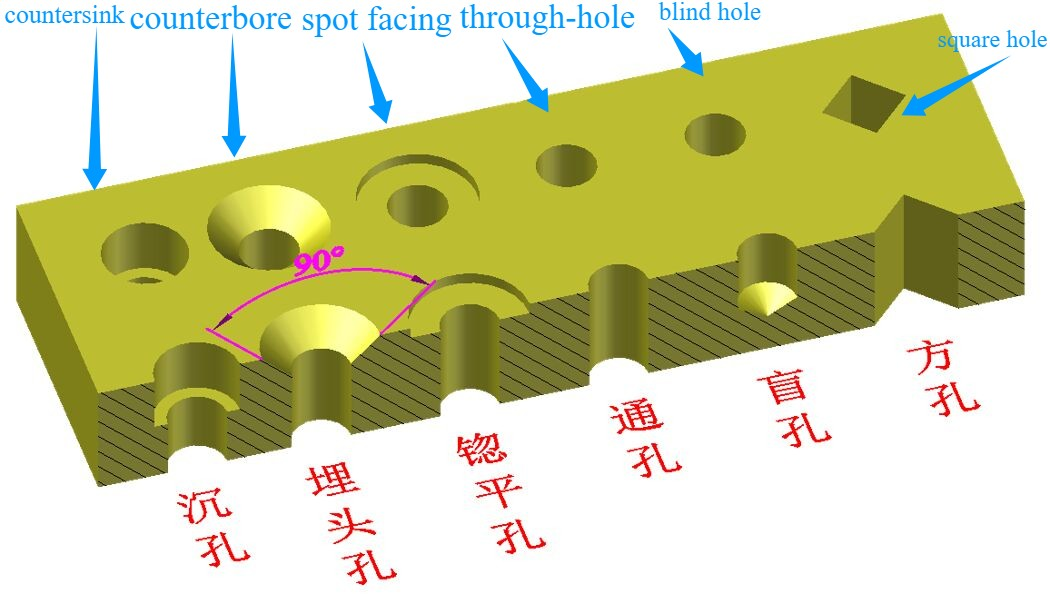

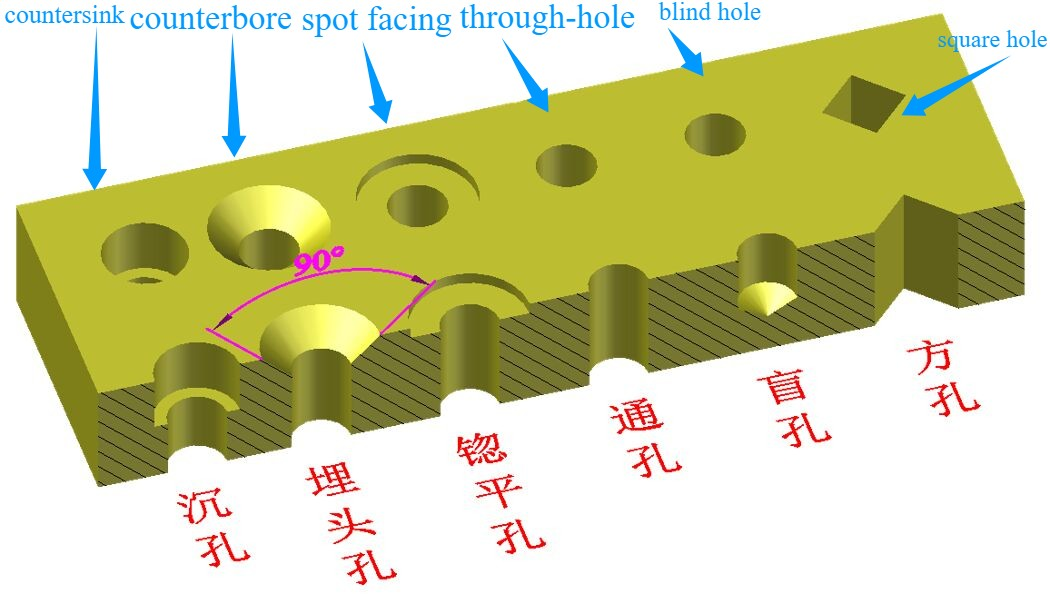

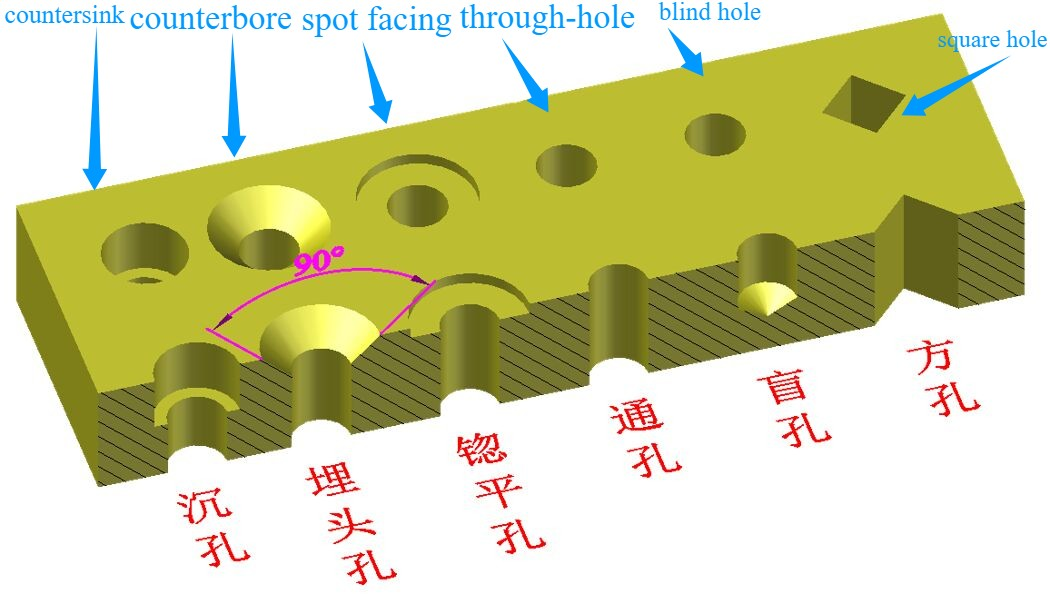

2024-08-02 CountersinkDefinition: Countersinking is a machining process that creates a larger diameter recess on the surface of a material, designed to accommodate the head of a screw so that it sits flush with or below the surface. Characteristics:1. Appearance: Features a larger diameter recess, typically co

Read More

2024-07-31 Powder coating and spray painting are two common methods used to apply a protective or decorative finish to surfaces. Each method has distinct advantages and characteristics that make them suitable for different applications. Powder coating involves applying a dry powder to a surface, which is when

Read More

2024-07-24 MIM Processing, also known as Metal Injection Molding, is a forming method that involves injecting a mixture of metal powder and a plasticizing binder into a mold. It's a manufacturing process used to produce complex metal parts in large quantities with high precision. This technology combines moder

Read More